microDAC® measuring systems for non-destructive material testing

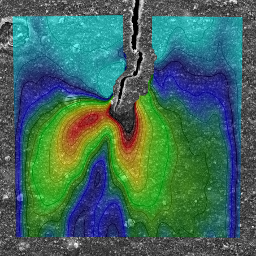

microDAC® measuring systems are modular high-performance systems for non-destructive material testing using 2D analysis of movements, deformations and strains based on digital image correlation (DIC).

The measuring systems work on the basis of a highly accurate digital image correlation method (DIC) and use the natural structure of the measured object surface to determine the smallest local

displacements and strains. Sample preparation is only required for transparent and shiny materials.

The microDAC® measuring systems have a wide range of applications in science and technology and are used by numerous companies, research institutes and universities for materials testing, product development and reliability analysis.

The universally applicable microDAC® measuring system is a modular high-performance system for non-destructive material testing using 2D analysis of movements, deformations and strains based on digital image correlation (DIC).

on the basis of digital image correlation (DIC). The systems are characterized by a high flexibility of the optical setup and allow you a comfortable and time-effective evaluation.

More »

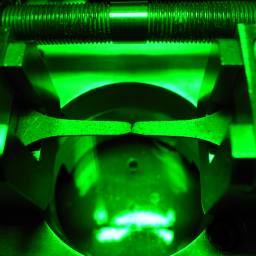

The Video Extensometer - microDAC® strain is a DIN EN ISO 9513-certified video extensometer for tensile/compression tests, with which the longitudinal and transverse strains are simultaneously measured directly on the specimen surface (without additional markings).

transverse strains are measured simultaneously without contact and with high precision directly on the specimen surface (without additional markings).

More »

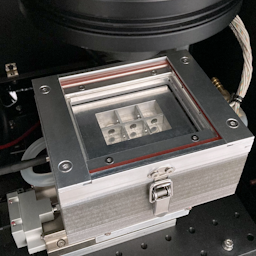

Our microDAC® CTE measuring device offers a fast and fully automatic measurement that is ideal for efficient use in material analysis. Fully automatic!

A highly accurate, non-contact measurement is carried out in two spatial directions (x, y) and up to 6 material samples can be tested in parallel! -> 12 CTE values simultaneously! -> Temperature range -40°C to 300°C!

More »

VEDDAC Software

The VEDDAC software solutions are user-friendly and intuitive image analysis tools that can be used to perform displacement and strain analyses based on the gray value correlation method (DIC, DVC).

VEDDAC processes images from a wide variety of image sources and image formats, uses intelligent evaluation algorithms for the highest possible measurement resolution and offers display and export options for the measurement results adapted to the measurement task.

VEDDAC and VEDDAC strain are part of our microDAC® measurement systems.

However, you can also purchase our VEDDAC, VEDDAC strain, VEDDAC volume and VEDDAC py software separately and use it to analyze the images/image sequences from your tests or load experiments.

VEDDAC is a universal, precise and user-friendly software for analyzing deformations and surface changes that impresses with its flexibility, versatile export options and compatibility with a wide variety of image sources.

More »

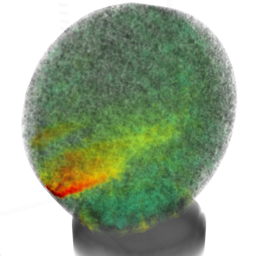

VEDDAC volume is a measurement software for characterizing structural changes inside materials.

The method is based on 3D volume correlation (DVC - Digital Volume Correlation) on radiographic data. VEDDAC volume is a versatile and precise

software for three-dimensional volume analysis that uses innovative algorithms to visualize deformations and structural changes in CT data while offering flexible export and visualization

options for a variety of applications. 3D slice images and semi-transparent 3D illustrations allow you to localize and highlight even the smallest material changes.

More »

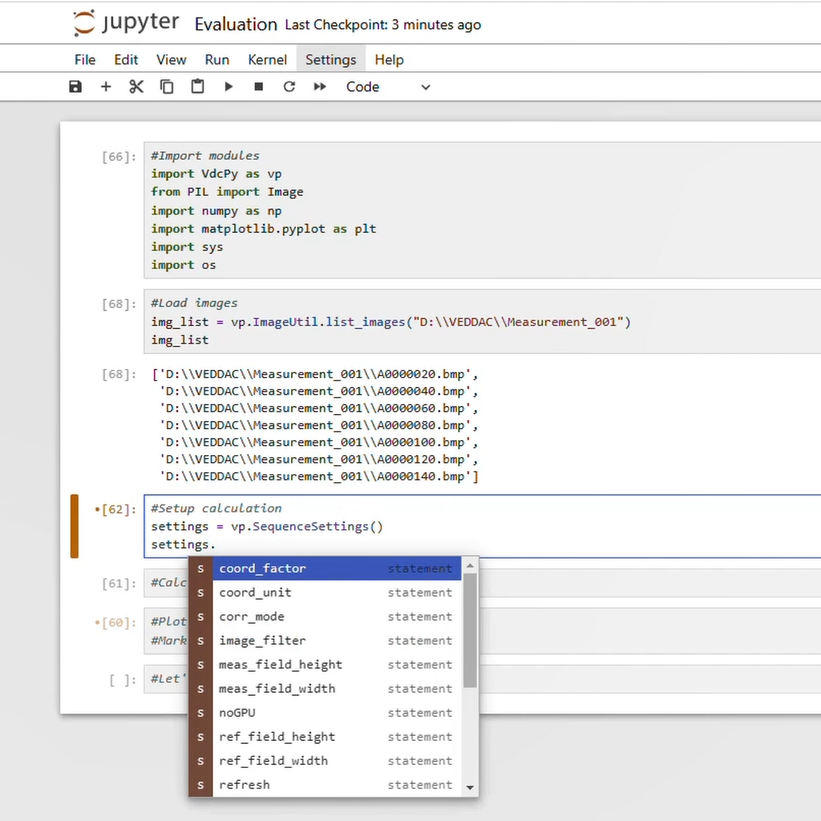

With VEDDAC py, you create the basis for time-efficient and modern process automation. Whether interactive applications, batch processing of large amounts of data or AI-based analyses - our Python interface opens up a wide range of applications for you.

With VEDDAC py you can seamlessly integrate the powerful image correlation algorithms of VEDDAC into your Python environment.

We enable automated digital image correlation (DIC) through the script-controlled execution of VEDDAC's image correlation algorithms.

More »