We offer precise measurement and analysis services with our microDAC® systems for digital image correlation and - in combination with X-ray computed tomography - for digital volume correlation.

Our methods enable the investigation of thermal and mechanical loads (e.g. tension, compression, bending) and are used in material and component testing, deformation and damage analysis and the reliability assessment of electronic components.

We support you in research projects and develop customised software and hardware solutions for motion and deformation analyses.

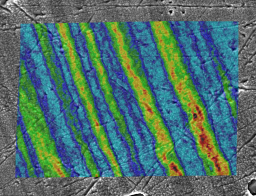

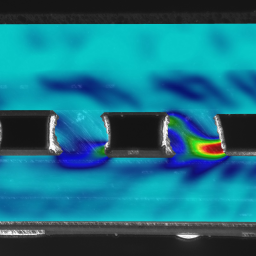

Whether 2D image data or CT volume data: We analyse your test images with our software solutions VEDDAC 7 (for digital image correlation) and VEDDAC volume (for digital volume correlation).

More...

We offer deformation and strain measurements for the analysis of failure mechanisms or the determination of material parameters both on the specimen surface and inside the specimen. Measurements can be carried out in-house or on your premises.

More...

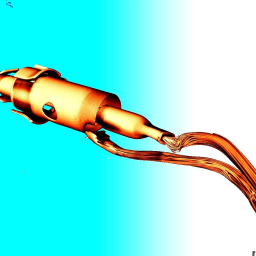

The radiographic image allows a view into the interior of components in order to identify possible causes of failures and to find any malfunctions.

More...

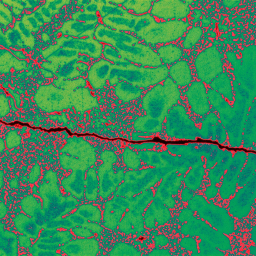

Metallographic microsection analysis is a preferred method for visualizing the microstructure of materials and composites. The method is used, among other things, to find possible causes of failures and malfunctions. In the case of such tasks within the scope of damage analyses, a preliminary X-ray inspection is advisable in order to enable target preparation to conspicuous locations.

More...