The microDAC® measuring system is a universal, optical measuring system for the precise recording of displacements, deformations and strains in the 2D range.

It offers a customised solution for non-destructive material testing based on digital image correlation (DIC). The system can be used from micro to far into the macro range and utilises robust correlation algorithms that deliver reliable results even in real measurement environments with spontaneous image influences. The 2D measurement enables highly accurate resolutions, whereby 3D movements can often be broken down into 2D components and analysed in detail. With a measured value resolution of up to 0.01 pixels, the microDAC® system enables convenient and time-efficient analysis of mechanical material properties.

The system is used in:

- testing of materials, components and systems in microelectronics

- the determination of material parameters

- fracture mechanics analyses, for example to investigate crack propagation or the adhesion of material composites

- The measurement of the swelling and shrinkage behaviour of materials exposed to moisture and temperature

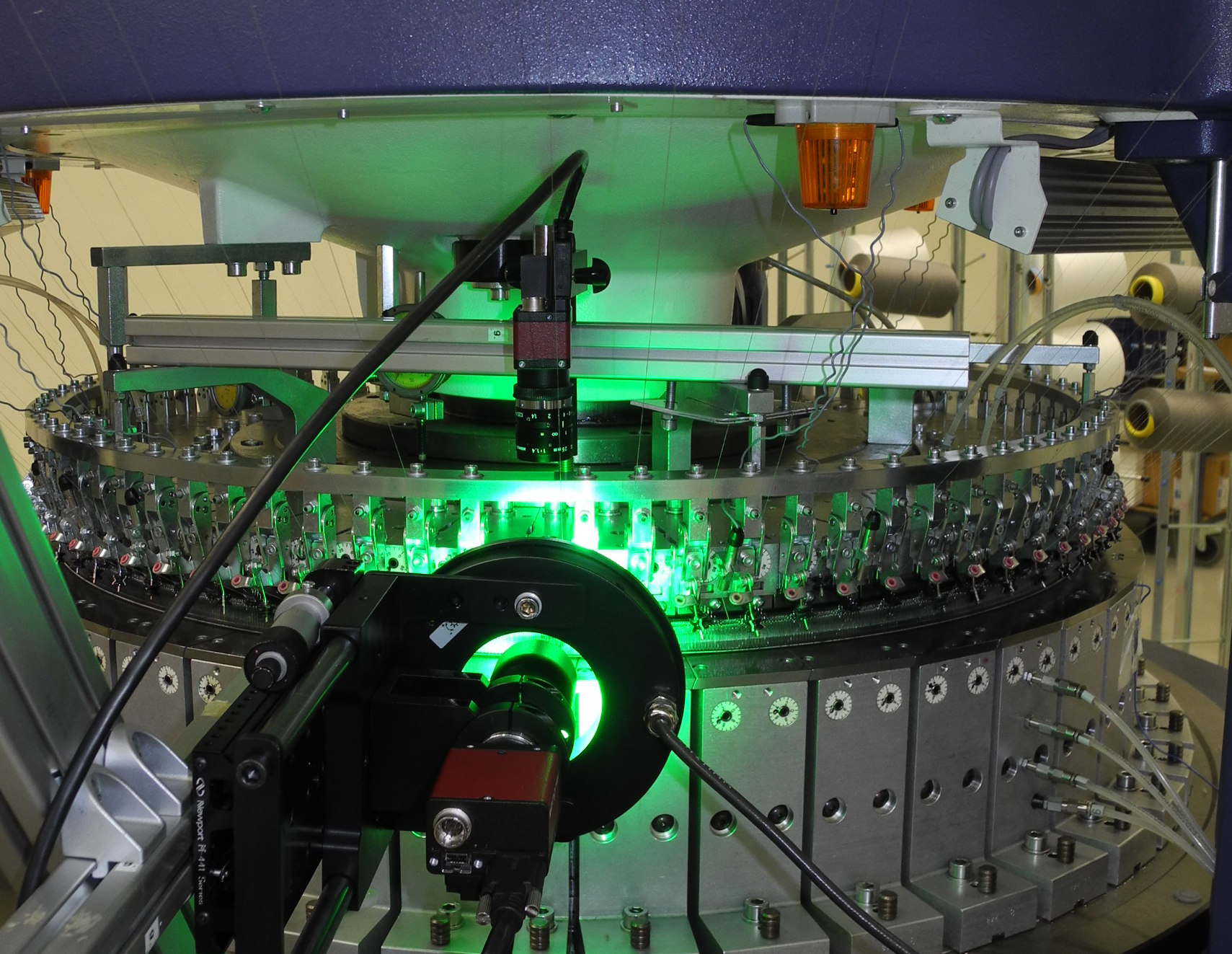

- the investigation of mechanical and thermal deformations on machines (e.g. textile machines, wire drawing machines)

- distance and speed analyses